MBH SOLUTIONS has partnered with major industrial supplier who has years of expertise in offering turnkey Process system and control to our esteemed customers for Soft drinks and Juice market. Together with our partner companies, we could not only assist you with municipal maintenance of parts and accessories demands for your current CSD and JUICE Process systems, but we can also offer upgrading in your current framework as well as holistic supply of new JUICE & CSD complex processes. In the event of a crisis, our local staff is readily available to assist our satisfied consumers. Our native team’s years of expertise in planning and design, testing and commissioning, and after-sales services make it possible for our customers to avoid being forced to queue for days for an engineer to arrive from elsewhere.

RAW MATERIAL STORAGE

SUGAR DISSOLVING

CHARCOAL TREATMENT & FILTRATION

PASTEURIZATION

STORAGE& DIVERTER PANEL

INGREDIENTS/FLAVOR MIXING

INGREDIENTS/FLAVOR MIXING

RAW MATERIAL STORAGE & HANDLING

Bulk products gear is developed for involved transporting sugar safely and efficiently. The integrity of these raw materials is a crucial foundation for service quality. The primary goal is to give customers alternatives for securely managing and storing the product, such as silos, holding sacks, or large bags, to sustain the service performance. The storage and handling systems may be tailored to fit the open spaces and needs. Fragile products are pushed to the production employing discharge tools, and barrels are opened, emptied, cleaned, and crushed in preparation for disposal that is being poured. We provide both mechanical and hydraulic transport networks. All of our systems operate nearly without interruption and can be periodically cleaned.

SPECIFICATION:

Capacity: 2000 Kg/h – 30,000 Kg/h

Material: AISI 304 or as per customer requirement

Control: VFD & SIEMENS PLC S7 & TIA PORTAL

SUGAR DISSOLVING

MBH offers Continuous Sugar Dissolver, a fully automated continually dissolving unit for dissolving sugar in water. The advantages of continuous automatic dissolvers are.

- Short Syrup Production Time

- Continuous monitoring of Brix and provides constant sugar Brix throughout production

- No impact of sugar sack weight difference

- Higher yields

- Highly energy efficient thus reduces the cost for Energy consumption such as steam

- Less Space required for installation and no additional tanks needed

- Integrates with existing simple syrup production systems

- In built CIP system for easy and abrupt cleaning and integrates with existing CIP systems

SPECIFICATION:

Capacity: 2000 L/h – 30,000 L/h

Brix: 59 – 67 °Brix

Temperature: 40 – 85 °C

Material: AISI 304 or as per customer requirement

Control: SIEMENS PLC S7 & TIA Portal

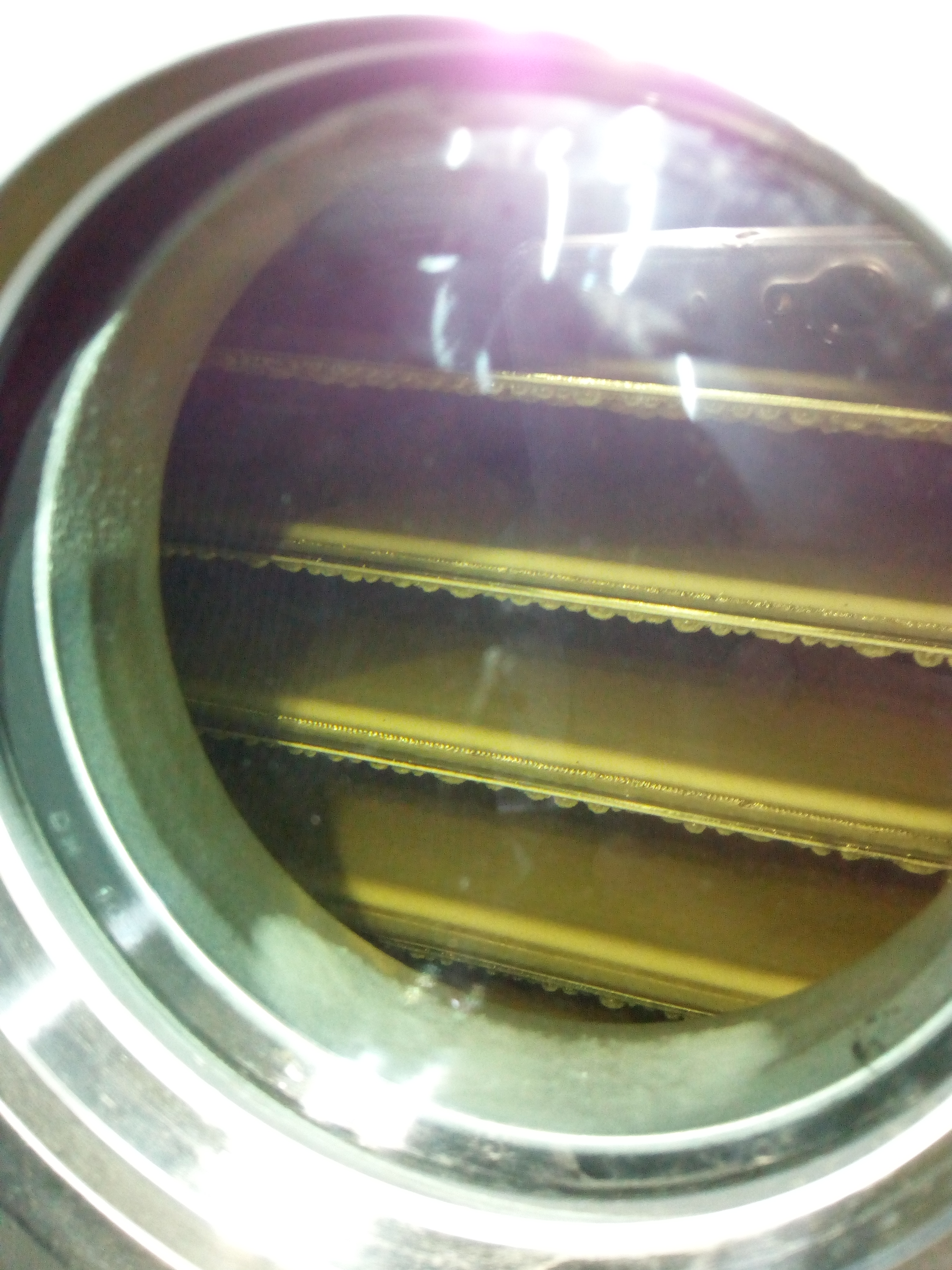

CHARCOAL TREATMENT & FILTRATION

Based on sugar quality such as ICUMSA and Turbidity value, the activated carbon treatment system is employed to improve the desired quality parameters. The sugar syrup is mixed with activated charcoal using an automated dosing system and a desired contact time is achieved.

To clean the impurities and the dosed activated charcoal, MBH along with its partners offersfiltration solutions for filtering of sugar syrup based on two reliable and tested technologies.

- Kieselgur filtration based devices for filtering liquid media in beverage preparation. For such purpose, horizontal stainless steel based filtering elements which are packed over each other on a single shaft, are employed. Also on the request, the sheet based filtering system is provided.

- The second option for filtering the simple syrup is using an ion exchange decolourisation systems which remove the product’s impurities.

PASTEURIZATION

Respective product requirements, plate or pipe heat transfer are employed in several operations:

- In flash pasteurizers, such as those used to purify sugar syrup

- In hot filling procedures

- In cold antimicrobial filling methods (e.g. UHT)

- Heat recovery is deployed to boost efficiency, as a result, reduce energy costs.

- All systems are PLC regulated with programmable variables.

SPECIFICATION:

Capacity: 2000 L/h – 30,000 L/h

Temperature: 85 °C

Pasteurization time: up-to 140 s (as per the product requirement)

Material: AISI 304 or as an option AISI 316L

Control: SIEMENS PLC S7 & TIA Portal

STORAGE SYSTEM & DIVERTER PANEL

Pasteurized simple syrup will be kept in elevated vessels for later use in the blending process. Our tanks are meticulously designed, constructed, and properly sanitized for this purpose. A robust air filtering system is installed at the reservoirs.

Different kinds of material flow media are used to transfer simple syrup from reservoirs to the mixing unit and mixing containers.

MBH offers following options for our customers,

– Manual Divert Panel

– Automatic Divert Panel with or without dip tray

SPECIFICATION:

Capacity: 2000 L/h – 30,000 L/h

Temperature: ambient

No of Tanks: up-to 8 Tanks per divert panel OR as per actual layout

Material: AISI 316L or as per requirement

Control: SIEMENS PLC S7 & TIA Portal

Ingredient/Flavor Mixing Stations

MIXING is the generic term used to describe a significant number of wet ingredients to the main product, which is commonly water or simple syrup. The mixing procedure fluctuates based on the products and the production steps: the merging will use concentrations and/or water and carbon dioxide. A recipe control framework is included with highly automated setups. The blending procedure for fruit juices also includes pulp and fibers. With the help of our principles, we can provide our users with a wide of premium solutions. The following includes, but is not confined to:

- Pekin Dissolving Station

- Automatic component mixing depending on a formula

- Manual Concentrate Station

- Moveable Concentrate Trolley

- Drum Emptying Station

FINISH SYRUP PROCESS SYSTEM

After combining the various essential components with base water or syrup, the mixture is delivered to mixing tanks for final integration and storage of Finish Syrup. To manage the fragile substance, the combining tanks are meticulously developed, built, and coated. The ready to filled syrup is sent to filling lines using an automatic supply system which is linked with filling lines in order to coordinate the required filling requirement at different production steps.

SPECIFICATION:

Tank Capacity: 5000 L – 50,000 L

Temperature: ambient

Diver Panel Capacity: up-to 8 Tanks per divert panel OR as per actual layout

Material: AISI 316L or as per requirement

Control: SIEMENS PLC S7 & TIA Portal / Manual